A fan inspired by a model made by AEG in the 1900’s

!!! WARNING: ARTICLE UNFINISHED - PARTS ARE MISSING !!!

The fan was originally designed by Prof. Peter Behrens (1868-1940) in approx. 1908 for the AEG-Company. Behrens was a designer, architect and artist and is recognized as a pioneer of industrialdesign. The exact modelname of the fan was “AEG Typ NOVU 2”.

Judging by pictures the fanblades aswell as the cage are made of brass, while the rest seems to be made from bakelite.

Due to there not being a lot of information about this exact model, i had to assume most of the dimensions etc., aswell as use simular models as inspiration. Therefore the final fan-design is not a direct replica but more of a heavily inspired and modernized version of the original.

Details

- Power: USB (5V)

- speed: 0-x rpm

Components

-

Standard Hardware:

- 1mm brass sheetmetall

- ⌀2mm brass wire

- 13x M2x10mm hexhead-screw

- 11x M3*10mm slottedhead-screw

- 5x M3*5mm slottedhead-screw

-

Electronics: BOM

Course of action

CAD

The mechanical parts were designed using Fusion360 according to the approximated dimensions.

The complete 3D-model can be downloaded here.

3D-printing

The parts were 3D-printed from black PLA with a 0.4 mm nozzle on a CR10-S5 3D-printer. To get the flow of the kurve right, i used the minimum settings for my printer at 0.15 mm as the layerheight. Due to the small size of the prints aswell as to give the base more mass they were printed at 100 % infill.

After printing, the parts were sanded up to 2000 grid and then coated with 2 layers of black spraypaint, wet sanding again with 2000 grid sandpaper after the first coat. This results in a mirror-like surface-finish.

The mold for making the cage was printed seperatly using a 0.8 mm nozzle at 10 % infill with the default layerheight in Cura of 0.32 mm.

Machining the parts

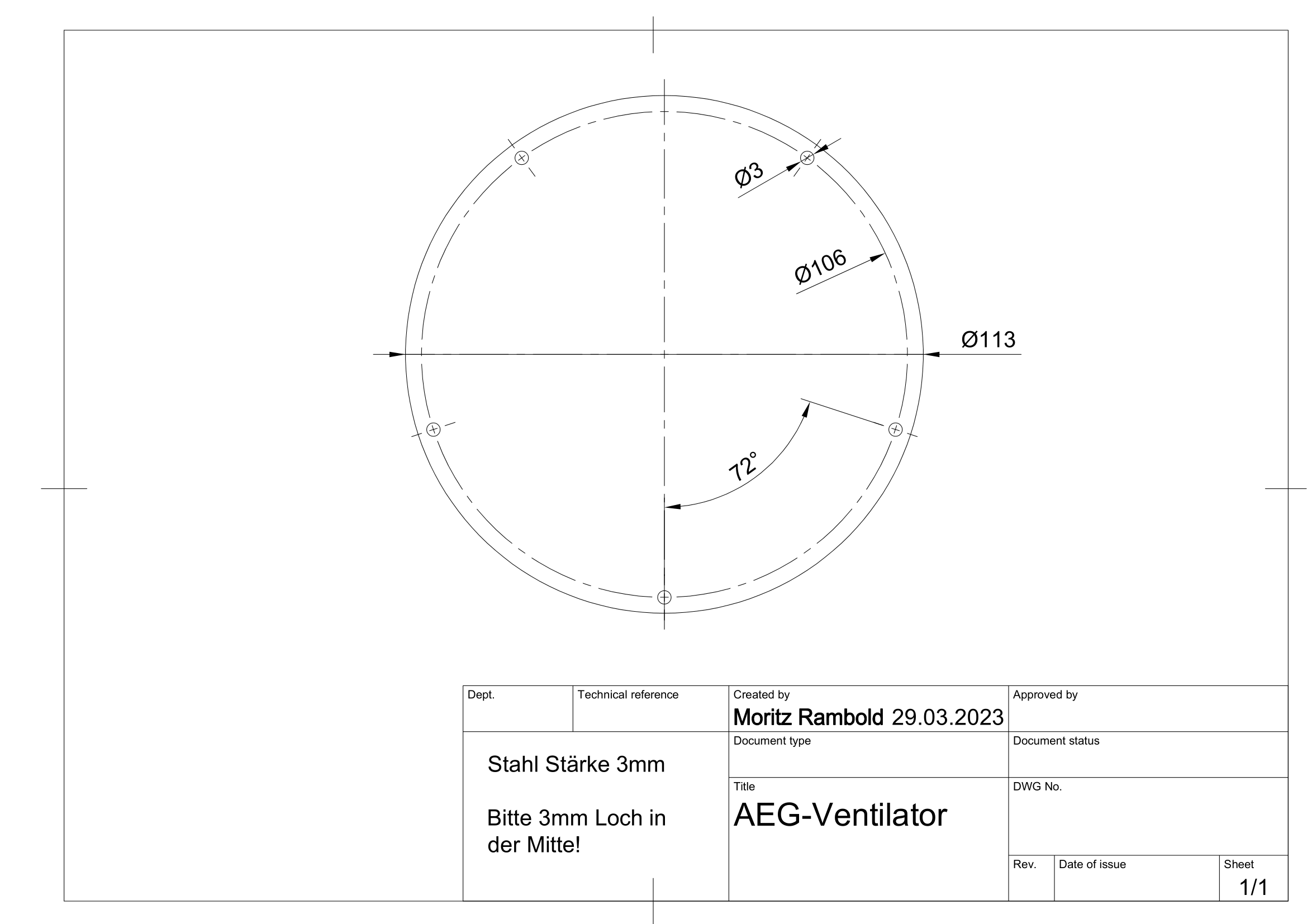

Baseplate

Because the base of the fan by itself wouldn’t be able to support the weight of the motor, cage and fanblades, it has a steel plate on the bottom. While adding some mass to the base, the plate simultaneously acts as the bottom cover. The plate is made from 4 mm thick steel plate and was machined by a friend (pfuschzone) according to the plans. For rustprotection it was coated with a quick layer of spraypaint. It is installed using screws (M3x5mm) from the outside.

Technical drawing for the base-plate here

Technical drawing for the base-plate here

The Propeller

COMMING SOON!

The Cage

The cage consists of 2 mm brasswire. To achieve the desired form, 8 pieces of wire were soldered to a central hub and then hamered into the grooves of the 3D-printed form. 2 Rings were bent from brasswire. were each wire was individually bend around and crimped.

To achieve the central AEG-logo, a round piece of brass-sheetmetal was hammered into a dish-shape and a ring of brasswire soldered on top. The text was simply cutout from paper, glued to the part an sprayed with a coat of spraypaint. The logo was mounted to the center using hotglue.

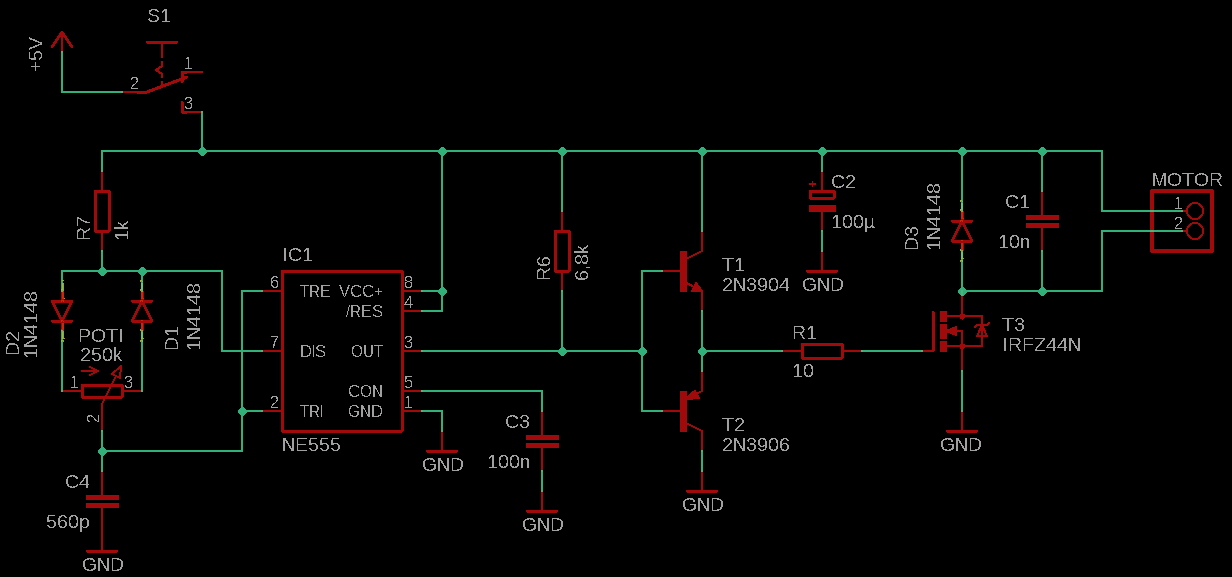

The Electronics

All electrical aspects were planned in the following document:

Schematic of fan

Schematic of fan

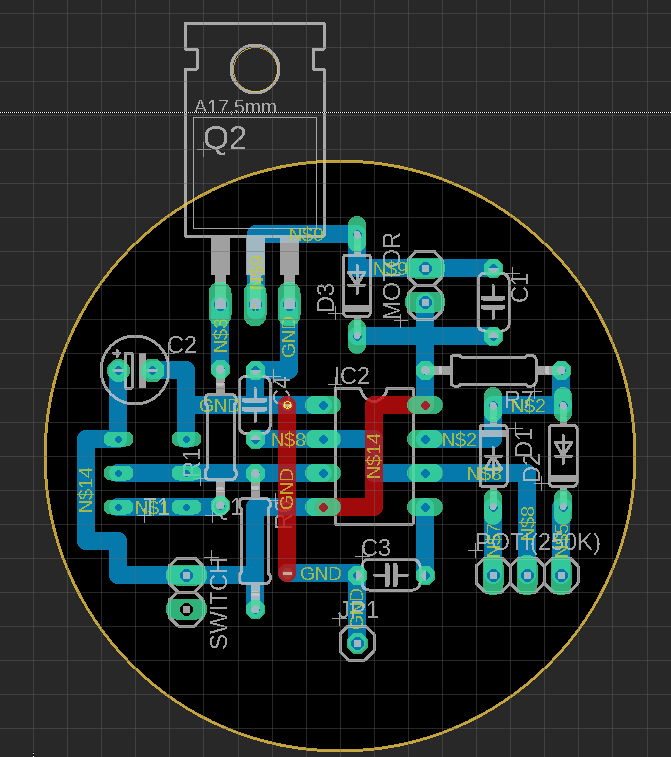

Perfboard layout of fan

Perfboard layout of fan

Issues

- unbalanced prop

- Middlepiece to thin, gets easily bentd

- Driver-Circuit inefficient

- Cage-mounting-brackets from PLA -> way to flexible